Introduction

Climbing, in all its forms, is a pursuit that combines physical strength, mental fortitude, and a touch of daring. As climbers ascend towering cliffs and navigate intricate bouldering problems, one unassuming tool plays a pivotal role in their success: climbing chalk. This simple substance has become an indispensable part of a climber’s gear, enhancing grip and confidence on the rock. But how did chalk become so integral to climbing? Let’s journey through the history of climbing chalk to understand its rise from a basic mineral to an essential component of the sport.

The Introduction of Chalk: A Gymnast’s Influence

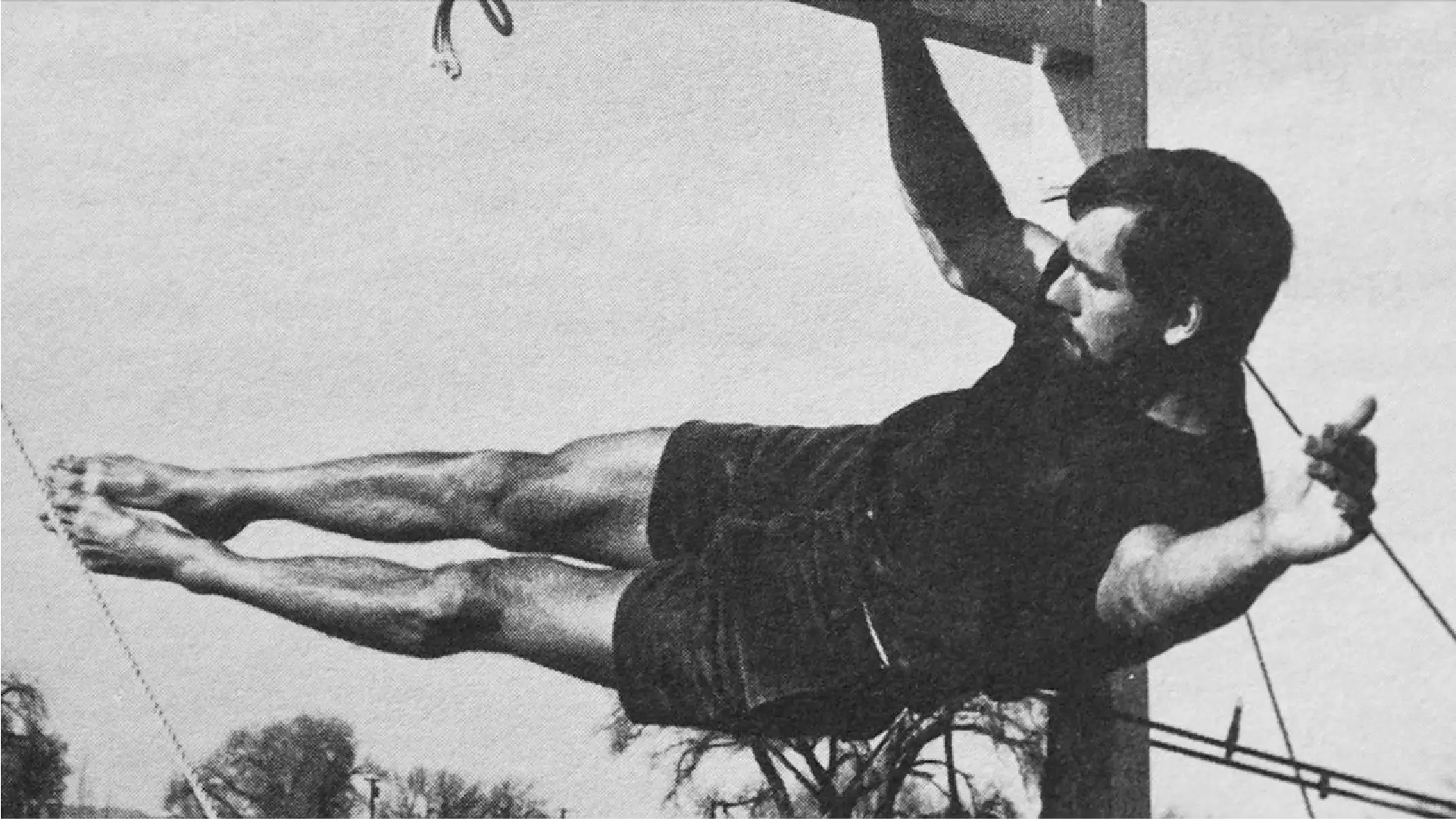

The turning point came in the mid-20th century with the introduction of magnesium carbonate, commonly known as climbing chalk. This substance was already in use by gymnasts to prevent slippage on apparatus like rings and bars. John Gill, an American mathematician and gymnast, is credited with pioneering the use of chalk in climbing during the late 1950s.

Gill applied his gymnastics experience to bouldering. Gill climbed V8 in 1957, V9 in 1959, and onsight free-soloed 5.12a in 1961. He found that chalk significantly enhanced his grip, allowing him to attempt harder problems with greater confidence. His successes and advocacy for chalk quickly spread through the climbing community, leading others to adopt this game-changing tool.

Chalk Becomes Mainstream

By the 1970s, chalk had become a staple in the climbing world. Equipment manufacturers began producing chalk specifically for climbers, along with accessories like chalk bags designed for easy access during ascents. The widespread availability of chalk allowed climbers to push the boundaries of the sport, tackling more difficult routes with improved safety.

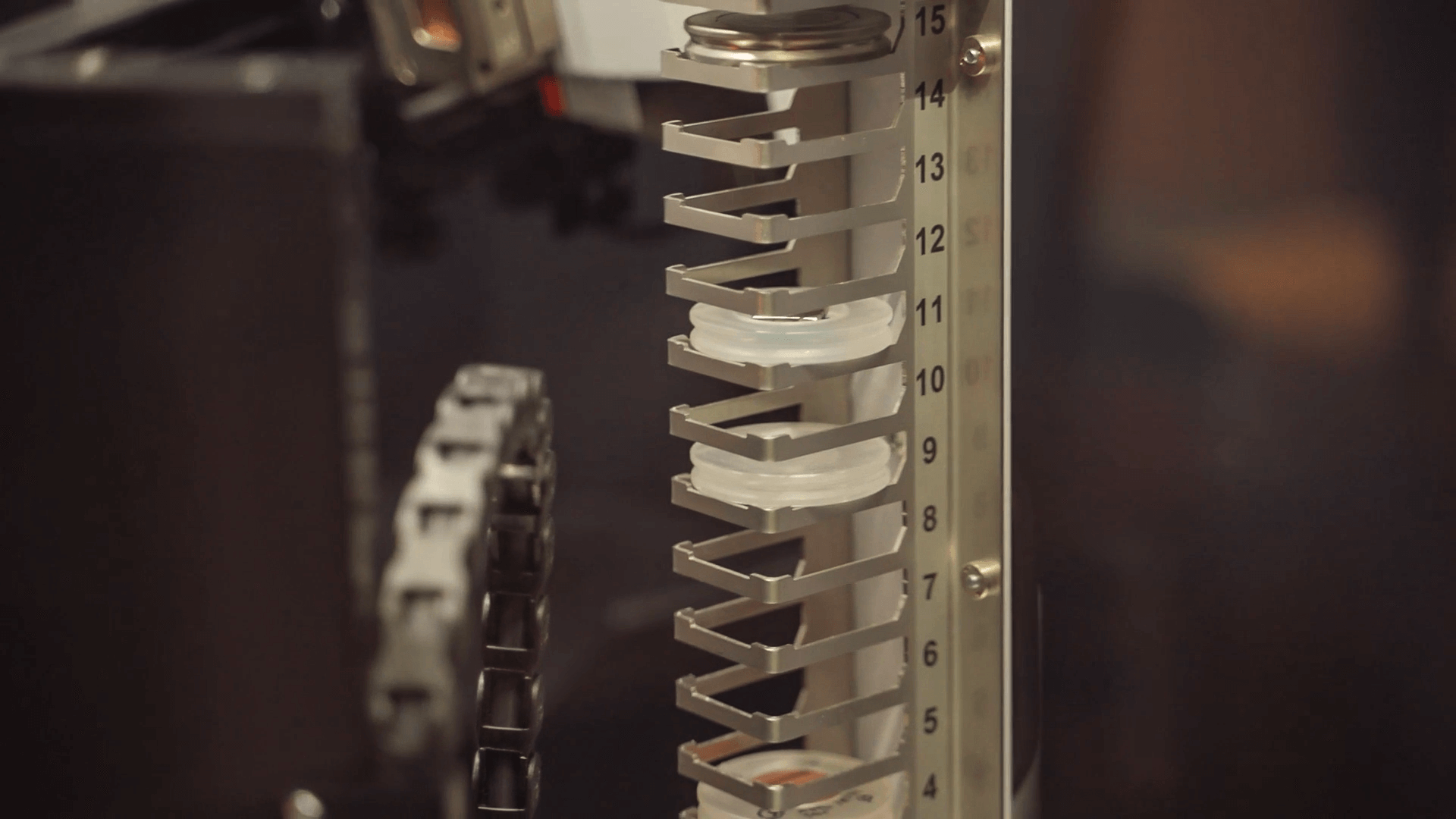

The following decades saw innovations aimed at enhancing chalk’s usability and environmental friendliness. Chalk balls—mesh pouches filled with chalk powder—were introduced to minimize spillage and waste. Liquid chalk emerged as a solution to reduce airborne particles in climbing gyms, offering a cleaner alternative that still provided excellent grip.

Rosin or POF and Regional Practices

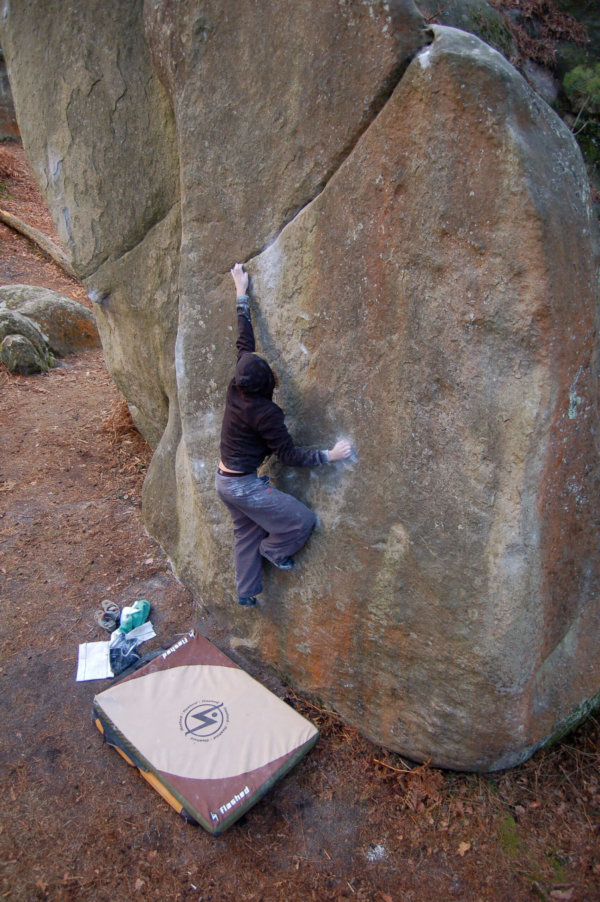

In the early days, particularly Fontainebleau in France, climbers experimented with using rosin or POF to enhance grip. Rosin, derived from pine tree sap, provides a sticky surface that can improve adhesion on the area’s unique sandstone boulders. However, its use is controversial. Rosin can leave a glaze on the rock, polishing the surface over time and altering the natural texture of the holds. This can make climbs more difficult or even damage the rock permanently.

As a result, the use of rosin is strongly discouraged. The local climbing community emphasizes the importance of preserving the rock for future generations, advocating for minimal impact practices and educating climbers about the consequences of using substances like rosin. However you will still find some of the old school French climbers still using POF.

What is Chalk?

The Science Behind the Grip

Magnesium carbonate (MgCO₃) is prized for its moisture-absorbing properties. When applied to the hands, it effectively reduces sweat, increasing friction between the skin and the rock surface. This allows climbers to maintain a secure hold even on challenging routes.

Magnesium carbonate (MgCO₃) is a white, crystalline solid with a variety of physical and chemical properties that make it useful in multiple industries. It is almost insoluble in water, but reacts with acids to release carbon dioxide, making it useful in applications requiring mild effervescence or buffering capabilities.

As a mineral, it commonly appears in nature as magnesite and dolomite, contributing to the composition of sedimentary and metamorphic rocks. Its high thermal stability and ability to resist decomposition at temperatures up to 350°C make it an effective material in fireproofing and as a heat-resistant component in ceramics and glass production.

In sports, MgCO₃ is widely used as climbing chalk, where it absorbs moisture and enhances grip, improving athlete performance and safety.

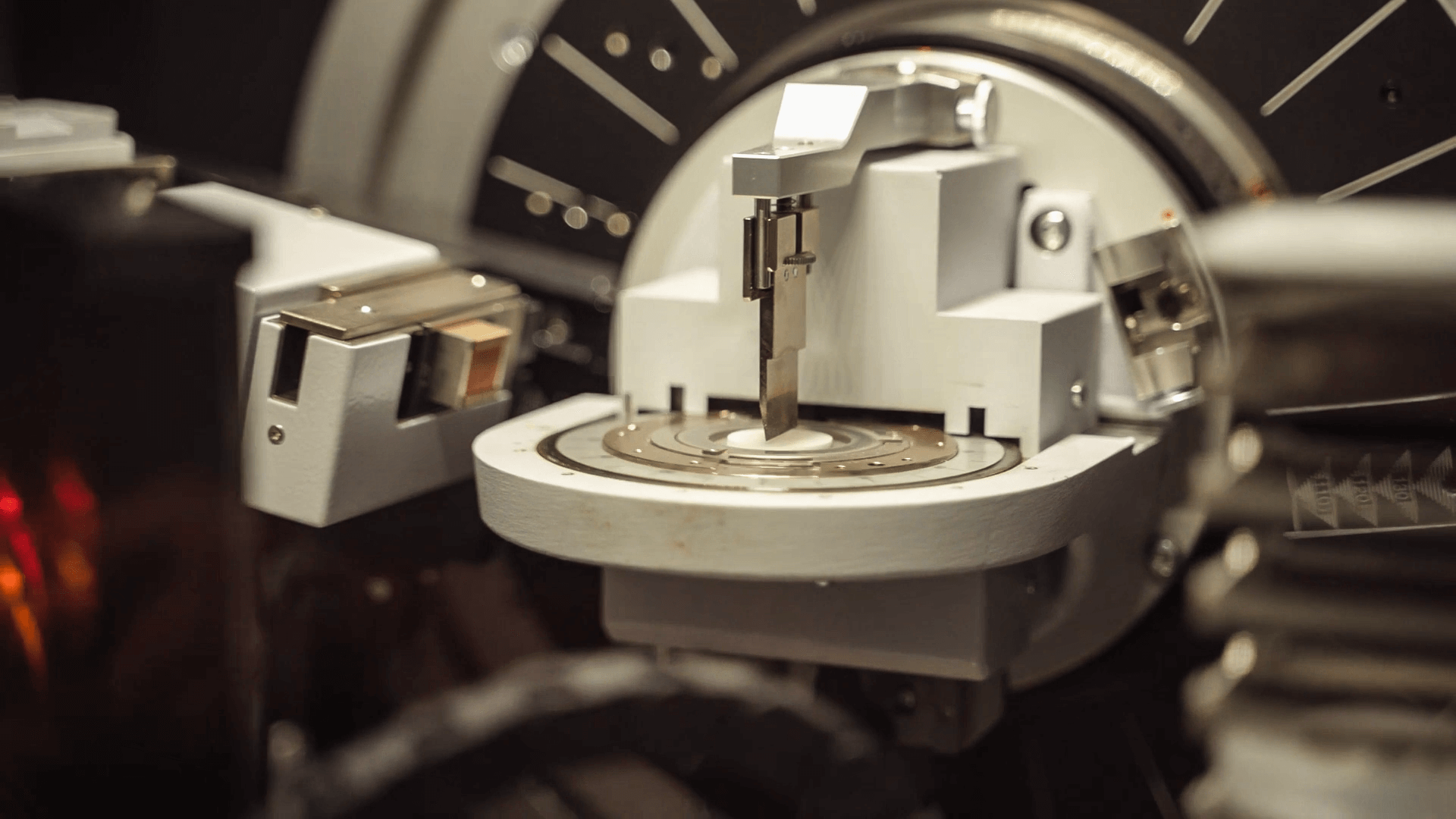

Mining of Magnesium Carbonate: Methods and Global Production

Magnesium carbonate used in climbing chalk is traditionally obtained from the mineral magnesite. The extraction process begins with mining magnesite ore through open-pit or underground methods, depending on the deposit’s depth and geography. Once extracted, the ore undergoes crushing and heating to remove impurities, resulting in high-purity magnesium carbonate suitable for various applications, including as a drying agent in climbing.

Globally, several countries are key producers of magnesite: China, Russia, Austria, Turkey, Brazil and Australia.

However, the practice of mining Magnesite has some worrying findings. One study examined the impact of alkaline and metal pollutants from a magnesium factory in Jelšava-Lubeník, Slovakia, on the local soil and vegetation. Researchers found that the area, considered one of the most environmentally damaged regions in Slovakia, had strongly alkaline soils with toxic levels of chromium, manganese, and magnesium. These contaminants negatively affected soil pH, plant diversity, and vegetation cover. Additionally, harmful levels of heavy metals were detected in both the soil and in plant species, indicating significant environmental contamination.

By understanding the origins and production methods of magnesium carbonate, climbers can make informed choices about the chalk they use. Whether opting for traditionally mined chalk or seawater-derived alternatives, the key is balancing performance needs with environmental responsibility—a consideration that continues to shape the future of climbing equipment.

The Rise of Seawater-Derived Chalk

In recent years, the climbing industry has seen the introduction of seawater-derived magnesium carbonate, often referred to as “seawater chalk.” This innovation emerged as a response to the growing demand for environmentally sustainable products among climbers. Traditional mining of magnesium carbonate can have significant environmental impacts, including habitat disruption and carbon emissions from extraction processes. Seawater chalk offers a greener alternative by utilizing magnesium extracted from abundant seawater resources.

The process of extracting magnesium carbonate from seawater involves precipitating magnesium ions using chemicals like calcium hydroxide. This method has been known for over a century but became commercially viable for climbing chalk production in the early 21st century due to advancements in technology and increased environmental awareness. Companies began marketing seawater chalk in the 2010s, highlighting its reduced environmental footprint compared to mined counterparts. This sustainable sourcing aligns with the climbing community’s ethos of preserving natural landscapes and minimizing human impact on the environment.

Affect on Performance

GRIP

Several studies highlight the efficacy of chalk in enhancing grip performance for rock climbers. A 2018 study aimed at assessing chalk’s impact on open-handed and pinch grip weighted assisted pull-ups (WAPU) among trained recreational climbers found that chalk use significantly increased the number of pull-up repetitions in both grips (p = 0.006 for open-handed, p = 0.007 for pinch grip) compared to non-chalked trials. This aligns with a 2012 study published in *Sports Biomechanics*, which demonstrated that chalk improves the friction between climbers’ fingers and rock surfaces like sandstone and limestone by approximately 19% and 22%, respectively. Interestingly, this study noted that humidity and temperature did not affect the grip, suggesting that other factors may influence how climate impacts finger friction in rock climbing.

Contrastingly, a study published in the *Journal of Applied Biomechanics* investigated chalk’s effect on climbers’ grip and muscle activity and found that while chalk did not significantly change friction, body movements, or muscle activity, climbers were able to hang significantly longer when using chalk—about 63 seconds compared to 49 seconds without it. This suggests that chalk enhances grip endurance, allowing climbers more time to rest and strategize their next moves, ultimately improving climbing performance. Collectively, these studies support the continued use of chalk during training and competition and highlight the potential for future research to explore different types of chalk and climbing holds to further understand their effects on performance.

Environmental Considerations and Ethical Debates

Environmental