In the world of climbing, every grip counts. That’s why we’re thrilled to introduce Mg2+, our groundbreaking seawater climbing chalk that’s set to redefine the standards of performance and environmental stewardship in the climbing community.

Climbing chalk is essential for climbers, providing the grip needed by absorbing moisture (sweat) from their hands. The primary component of climbing chalk is magnesium carbonate (MgCO3), but the source and production process can vary significantly between seawater chalk and mined climbing chalk. Here’s an overview of the differences:

Seawater Climbing Chalk

- Source: Seawater climbing chalk is derived from seawater. It’s produced by extracting magnesium ions (Mg2+) from seawater, which are then converted into magnesium carbonate through a chemical process.

- Production Process: The process involves pumping seawater into controlled environments (like baths) and adding reagents to precipitate magnesium carbonate out of the solution. The method is relatively eco-friendly, as it avoids the direct extraction of minerals from the earth and can minimize land and habitat disruption. Innovations in this area, like the Mg2+ product, focus on reducing environmental impact further by using pre-cycled materials for packaging and ensuring the process is as sustainable as possible.

- Environmental Impact: Generally lower than mined chalk, especially if the process is designed to minimize energy use and avoid harmful byproducts. The return of treated seawater to the ocean and the use of recyclable materials for packaging are additional eco-conscious measures.

Mined Climbing Chalk

- Source: Mined climbing chalk is directly extracted from the earth. It’s sourced from natural deposits of magnesium carbonate which have formed over millions of years.

- Production Process: This involves traditional mining techniques to extract magnesium carbonate from the earth. The process can be more invasive, involving drilling, blasting, and transporting raw materials from mines, which can have significant environmental impacts, including habitat destruction and pollution.

- Environmental Impact: Typically higher than seawater chalk due to the nature of mining operations. The extraction process can disrupt local ecosystems, and the carbon footprint associated with mining and processing is often significant.

Comparison Summary

- Environmental Sustainability: Seawater chalk tends to have a lower environmental impact compared to mined chalk, given its more sustainable production processes and efforts to minimize ecological footprints.

- Purity and Performance: Both types aim to provide high-quality magnesium carbonate for optimal grip. However, seawater chalk can often be purified further during its production process, potentially offering a purer product, as seen with the Mg2+ chalk that undergoes XRD testing for purity.

- Innovation and Sustainability Focus: Seawater chalk, like Mg2+, often emphasizes innovative production techniques and sustainable practices, from extraction to packaging, aligning with the growing demand for eco-friendly outdoor sports products.

In summary, while both seawater and mined climbing chalk serve the same fundamental purpose, their differences in sourcing, environmental impact, and production processes reflect broader choices in the climbing community’s values and priorities, especially concerning sustainability and ecological responsibility.

A Leap Forward in Sustainable Packaging

At the heart of Mg2+ lies our commitment to sustainability, starting with its packaging. We’ve taken a stand against conventional packaging norms by opting for a pre-cycled and recyclable container. Made entirely from recycled materials, our container is a testament to our no-plastic policy, embodying our dedication to the planet without compromising on quality or functionality.

Innovative Extraction for Minimal Environmental Impact

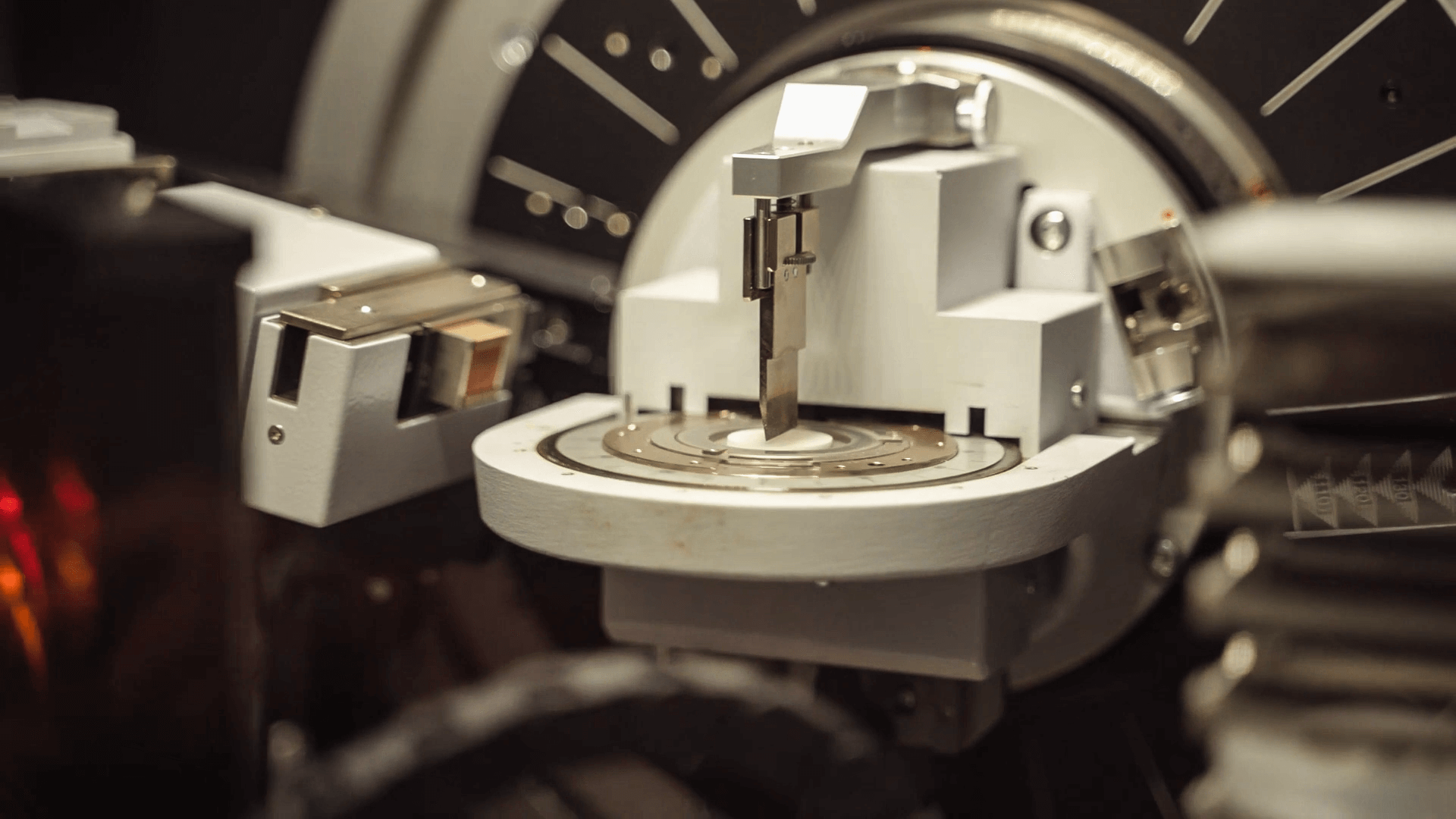

While traditional seawater chalk production methods involve flooding land with seawater and waiting for evaporation, and leaving the land damaged afterwards, we sought a more eco-friendly approach. Our innovative process involves pumping seawater into specialized baths, where, over a few weeks, we carefully extract the Mg2+ compound. This method not only names our product but also highlights our minimal impact philosophy. By returning the remaining seawater to the ocean and refining the magnesium carbonate through synthesis and X-ray diffraction (XRD) testing, we ensure a purer product that’s kind to the earth.

The Mg2+ Difference: Purity and Performance

What sets Mg2+ apart is not just our environmental ethos, but the unparalleled purity and performance of our climbing chalk. Our slow, specialized process allows us to precipitate magnesium out of seawater over 20 days, producing a high-purity magnesium carbonate that meets the demanding needs of climbers. The result? Enhanced grip, improved performance, and the peace of mind that comes from using a product that’s as good for the planet as it is for your climbing performance.

Our Promise: Sustainability at Every Step

Our journey with Mg2+ reflects a broader commitment to sustainability and innovation. By leveraging the by-products of the salt industry and minimizing land use, we’re not just creating a superior climbing chalk; we’re setting a new benchmark for environmental responsibility in the outdoor sports industry.

Climbers now have a choice that aligns with their values without sacrificing performance. With Mg2+, embrace the climb with confidence, knowing you’re part of a larger movement towards a more sustainable and responsible approach to the sport we all love.

Learn more about chalk’s effects on health here.